Corrugated or Standing Seam Roofing: The Best Choice for Your Home

Key Points:

- Choosing between corrugated and standing seam metal roofs involves balancing budget and looks with long-term durability.

- Corrugated metal roofs offer affordability and an industrial look with exposed fasteners; standing seam roofs provide a sleek look and concealed fasteners.

- Standing seam roofs offer superior weather resistance and a longer lifespan, while corrugated roofs have easier installation and lower initial costs.

Metal roofing systems have become increasingly popular among homeowners who prioritize durability, energy efficiency, and long-term value over traditional roofing materials. Two primary options dominate the residential metal roofing market: corrugated and standing seam systems, each having distinct advantages for different applications and architectural styles.

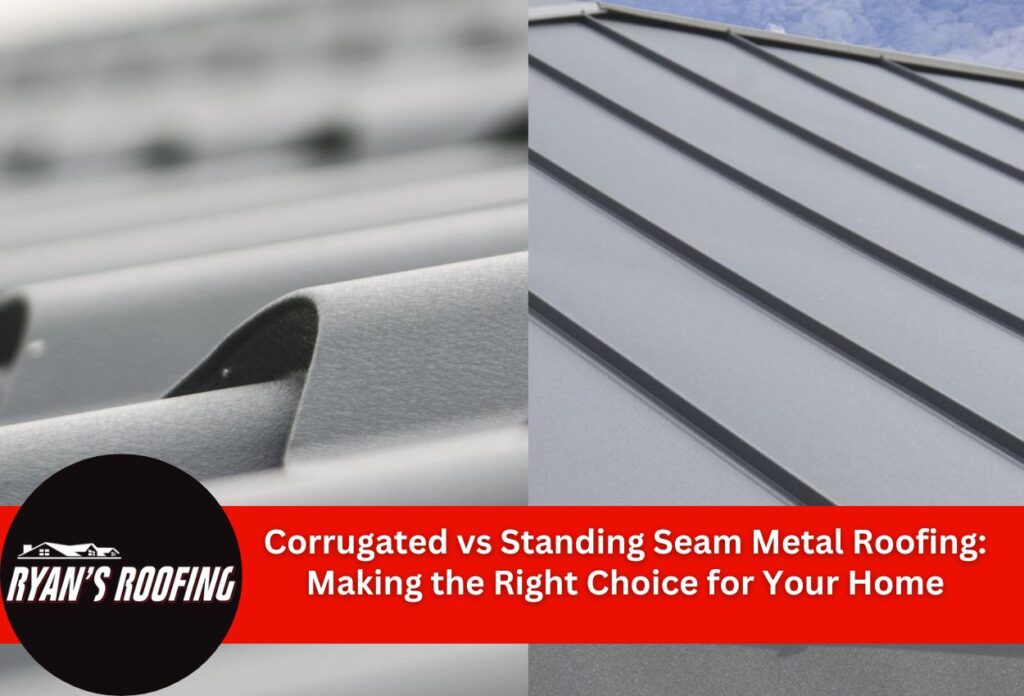

Corrugated metal roofing systems feature wavy ridges and valleys that create a classic, industrial appearance while providing excellent water drainage. This option appeals to homeowners seeking an affordable entry point into metal roofing without sacrificing performance. Standing seam metal roofs utilize interlocking panels with raised seams that run vertically along the roof’s surface, creating clean lines and superior weather protection.

The decision between these metal roof installation options depends on several critical factors, including budget constraints, desired curb appeal, and long-term performance expectations. Understanding the pros and cons of corrugated metal roofs and standing seam metal roofs helps homeowners make informed decisions that align with their specific needs and architectural requirements.

Understanding Corrugated Metal Roofing Systems

Corrugated metal roofing systems feature distinctive wave-like ridges and valleys that form the panel’s structural foundation. These alternating peaks and troughs create exceptional strength-to-weight ratios while allowing efficient water runoff during heavy precipitation. The corrugated design uses exposed fasteners that secure panels directly through the ridges into the roof deck, creating a straightforward installation process that reduces the complexity of labor.

The panel structure typically consists of galvanized steel or aluminum sheets formed into repeating curved patterns. This corrugated metal roof design provides rigidity without requiring additional structural reinforcement, making it an efficient choice when comparing metal roofing materials.

Standing Seam Metal Roofing Systems Explained

Standing seam metal roofing systems have sophisticated construction features that prioritize both curb appeal and weather protection. These panels utilize concealed fastening systems that secure the roofing material from beneath, eliminating exposed screws that can compromise weather resistance over time. The interlocking seams create continuous vertical lines along the surface of the roof while forming weatherproof barriers that prevent leaks at panel connections.

The premium positioning of standing seam systems in residential markets reflects their superior performance characteristics and refined appearance. Modern homes benefit from the clean, contemporary lines that complement architectural designs ranging from minimalist styles to traditional structures. Historic renovations often specify standing seam installations because the system provides necessary weather protection without compromising the building’s visuals.

Projects where curb appeal is a primary concern typically favor standing seam metal roofs over corrugated alternatives. The concealed fastener design eliminates the industrial appearance associated with exposed screw patterns, creating sleek profiles that enhance property values. When comparing metal roofing materials for residential roofs, standing seam systems consistently rank higher for homes prioritizing architectural sophistication alongside long-term performance reliability.

A Comparison of Performance and Durability

Weather resistance reveals significant differences when comparing corrugated to standing seam metal roofing systems. Standing seam panels excel in wind uplift resistance due to their concealed fastening systems, which eliminate weak points where exposed screws go through the metal surface. The interlocking seams distribute wind more effectively across the roof, providing superior performance in severe weather conditions. Corrugated systems rely on exposed fasteners that create potential failure points during extreme wind, though properly installed systems still offer excellent resistance for most residential properties.

Hail damage affects both systems differently based on the thickness of the panels and profile design. Standing seam metal roofs include smoother surfaces that deflect impacts more effectively, while corrugated profiles may show dents more readily in the valley areas. Thermal expansion management favors standing seam installations because the concealed clips allow panels to move naturally without stressing fastener connections.

Lifespan expectations typically range from 40 to 70 years for standing seam systems compared to 20 to 40 years for corrugated installations. Warranty differences reflect this performance gap, with standing seam manufacturers often providing longer coverage periods. Maintenance requirements remain minimal for both roofing types, though standing seam systems require less frequent fastener inspections due to their concealed mounting systems.

Installation Requirements and Complexity

Labor requirements differ significantly between corrugated and standing seam metal roof installations. Corrugated systems typically require basic roofing skills and standard tools, making them accessible to experienced contractors with conventional expertise. The exposed fastener system allows installers to secure panels directly through pre-drilled holes using standard screws and sealants. Most corrugated installations can be completed efficiently with basic measuring tools, drills, and metal-cutting equipment.

Standing seam metal roofing systems demand specialized training and professional-grade tools that increase installation complexity. Contractors must master seaming techniques using specific crimping equipment to create weatherproof connections between panels. The concealed fastener systems require precise alignment and specialized clips that secure panels from underneath while allowing thermal movement.

Roof preparation requirements vary based on the chosen system. Corrugated installations accommodate for slight imperfections in decking due to their structural flexibility, though solid sheathing remains essential. Standing seam systems require perfectly aligned decking with minimal irregularities to ensure proper panel alignment and seam integrity. Both residential metal roofing types benefit from synthetic underlayment, though standing seam installations often specify premium vapor barriers to maximize the system’s performance advantages.

Appearance Impact and Design Flexibility

Visual differences between corrugated and standing seam systems significantly influence architectural compatibility across various home styles. Corrugated metal roofing systems deliver a rustic, industrial look that naturally complements farmhouse designs, barn-style homes, and contemporary structures. The pronounced wave patterns create dramatic shadow lines that add visual depth and character to simple rooflines. Traditional residential buildings benefit from corrugated installations when homeowners desire authentic agricultural styling or modern industrial appeal.

Standing seam metal roof benefits include sleek, linear profiles that enhance sophisticated architectural designs. The vertical seam lines create elegant proportions that complement both contemporary minimalist homes and classic Colonial structures. Historical renovations often specify standing seam systems because the clean lines preserve architectural integrity while providing modern performance standards.

Color options can vary between the roofing types. Corrugated systems typically offer standard color selections in popular earth tones and primary colors, while standing seam installations provide extensive customization possibilities, including specialty finishes and architectural color matching. Paint system durability differs between options, with standing seam panels often featuring premium coatings that maintain color consistency longer. When comparing metal roofing materials for appearance, standing seam systems provide superior customization capabilities that accommodate specific design requirements and neighborhood architectural standards.

Making Your Final Decision

Choosing between corrugated and standing seam metal roofing systems requires evaluating initial investment against long-term value. Standing seam installations have higher upfront costs but have an extended service life, reduced maintenance requirements, and enhanced property values that often justify the premium positioning. Corrugated systems provide immediate affordability with solid performance characteristics, making them attractive for homeowners prioritizing functional protection over architectural refinement.

Pennsylvania’s climate conditions significantly influence material selection considerations. The state’s freeze-thaw cycles, heavy snow loads, and seasonal temperature variations favor standing seam metal roof benefits, including superior thermal expansion accommodation and enhanced ice dam prevention. Corrugated systems perform adequately in these conditions but may require more frequent fastener maintenance due to exposed screw connections experiencing weather stress.

Essential questions for roofing contractors should address installation expertise, warranty coverage, and local building code compliance. Verify contractor experience with your chosen system, request references from recent installations, and confirm proper licensing for metal roof installation options in your area. Ask about fastener warranties, paint system guarantees, and maintenance recommendations specific to Pennsylvania weather patterns when comparing metal roofing materials for your project.

Metal Roofing Services in Pennsylvania with Ryan’s Roofing LLC

Deciding between corrugated and standing seam metal roofing systems is a significant choice for any homeowner. Whether you prioritize budget, durability, or curb appeal, understanding the key differences can significantly impact your satisfaction and the roof’s long-term performance. Contact Ryan’s Roofing LLC, the trusted experts in metal roofing system installations across Pennsylvania. We are here to guide you through each step, ensuring that you choose the best option for your home.

Call us today at (717) 608-1587 and let Ryan’s Roofing LLC help you make the best choice for your home’s roofing needs.